Geological Bit Application

Release time:

2024-09-13

During construction, the geological drill bit should be applied scientifically, and the best use effect should be achieved by reasonably adjusting the bit pressure, rotation speed and pump capacity.

Application

● Under normal circumstances, the outer diameter of the reamer is 0.3-0.5mm larger than the outer diameter of the drill bit, and the hard formation is not more than 0.3mm.

● The matching between the drill bit and the circlip is reasonable. Normally, the inner diameter of the circlip is 0.3- -0.5mm smaller than that of the drill bit.

● Initial grinding shall be carried out when the new drill bit reaches the bottom of the hole: 1/3 of the normal drilling pressure and the rotating speed is about 100r/min, and normal drilling shall be carried out after 10 minutes of initial grinding.

● Before tripping in, measure the outer diameter of the drill bit and queue up for use according to the size and size to ensure that the drill bit goes down to the bottom of the hole normally.

● Sweep holes or clean residual cores with new drill bits, which will reduce the service life of the drill bit

● Check the drill bit. If abnormal conditions are found, it is strictly prohibited to use it in the hole.

● It is not recommended to use high matrix drill bits for broken formations.

weight on bit

Generally, the drilling should be controlled. Generally, the drilling in soft rock formation should be properly reduced to control the drilling speed; the drilling in complete or hard rock formation should be properly increased to improve the drilling speed; the drilling in broken, fractured or interactive formation should be properly reduced to ensure the drilling accuracy.

● Deep hole, inclined hole, over-diameter, tunnel drilling, the WOB is difficult to be guaranteed, it is recommended to choose the larger matrix material number of the drill bit, improve the drilling speed

Speed

● The linear speed of impregnated drill bit is 1.5-3. 0 m/s; The linear speed of surface-set drill bit is 1.0 -2.0 m/s; The linear speed of composite drill bit and alloy drill bit is 0.5-1.5 m/s.

● High rotating speed shall be adopted for drilling in complete hard rock stratum; the rotating speed shall be properly controlled for drilling in strata such as crushing, fissure, soft and hard interaction, etc.

● Full hydraulic drilling rig has stable performance and smooth operation, usually using high speed drilling

Pump capacity

●Reasonable pump capacity helps to cool the drill bit and discharge rock powder

● Select a smaller pump capacity for drilling in complete hard rock formations; increase the pump capacity for drilling in fractured and lost formations.

● High pump pressure is formed by large pump volume, which will have negative impact on drilling construction: seriously scour the bit matrix and reduce the life of the bit; scour the hole wall and cause instability of the hole wall

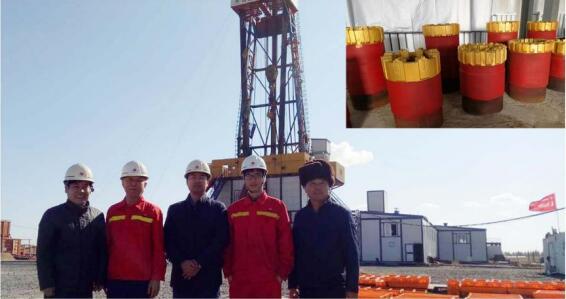

"Songke No.2 Well" construction site

Jinshi Drilling is one of the main participating units of the deepest continental scientific drilling "Songke No.2 Well" implemented by Asian countries. The drilling depth is 7018 meters. The project uses Jinshi drilling bits and tools, and some products are displayed in the national major scientific and technological achievements exhibition hall.

Related Information