The application of large diameter rope coring drilling technology in coal measure hydrological hole drilling is a new work!

Release time:

2018-09-29

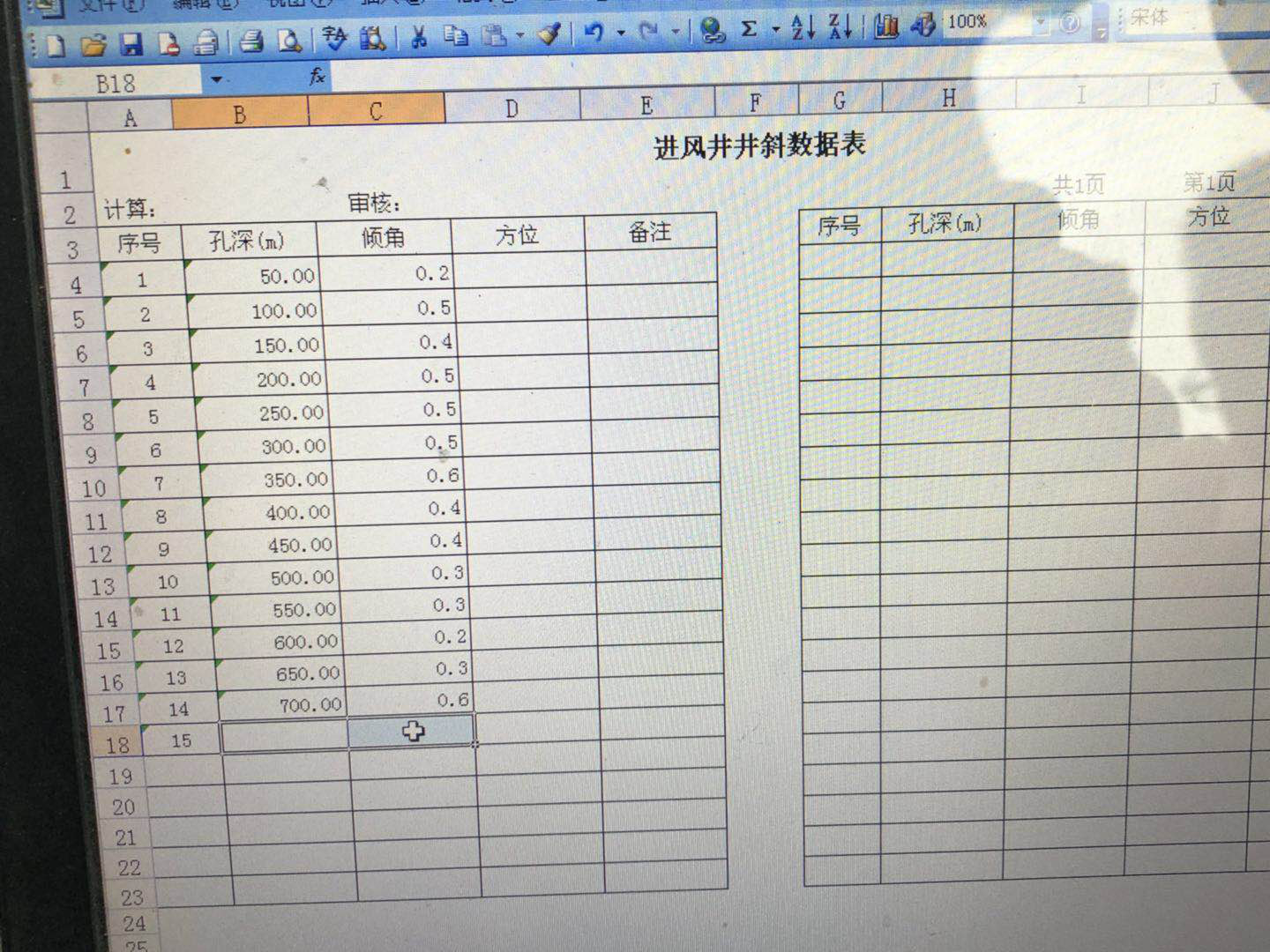

On September 27, 2018, the hydrological hole in the south column well of Sihe Coal Mine of Jinmei Group successfully ended. The project was contracted by JS01# machine of Jinshi Drilling. The drilling design depth was 700m. The drilling was started on August 25, 2018 and lasted 33 days. The final hole depth was 704.6m, the final hole diameter was φ122mm, the full hole core taking rate reached 97%, the hole inclination was controlled within 0.5 degrees, and the drilling quality greatly exceeded the expected by Party A.

According to Party A's technical requirements and innovative thinking of the construction machine, the new technology of large diameter rope core drilling is boldly adopted: φ168mm single pipe is drilled 40m and wellhead pipe is drilled; JS152 rope coring drilling tool, drilling to 478.6m, running Φ φ146mm casing to protect the well; JS122 rope coring drilling tool, drilling to 704.6m final hole.

The drilling process of large diameter rope coring has the following characteristics:

1. The new technology and reasonable gradation of large diameter rope core drilling run through the whole drilling construction process, and the new drilling concept of "efficient hole formation" is implemented;

2. The inner wall of the borehole is stable and smooth, the borehole integrity is good, the efficiency is high, the coal mine core taking rate is high, and the core sample integrity is high;

3, full-hole rope core drilling, core drilling tool stability is high, to provide a good environment for hydrological observation, improve the accuracy of logging data;

4. The adopted coal seam structure and thickness are completely consistent with the actual data, providing reliable geological, coal seam, hydrological and other technical data.

5. The new technology and reasonable gradation of large-diameter rope core drilling highlight the advanced nature of the concept of "efficient hole formation" in the field of rope core construction.

In the process of drilling quality evaluation, Party A (Jinmei Group) highly evaluated the construction progress, hole inclination control and construction management of Jinshi machine, and organized personnel to inspect and study the rope core drilling technology at the construction site, and the machine personnel answered relevant questions in detail. The rapid and smooth completion of the drilling also provides a strong proof for the rapid construction of large-diameter drilling by rope core drilling tools in coal strata.